Page 15 - RD_2000-12

P. 15

if l5mm sound tracks could be directly contact strain on the film now traveling at the higher

printed, Iiiii si:tc, on to l6mm picture prints, and speed of 18" per second. (Remember that in the

then nm, during pn~jcction at the correct linear 1930s much tri-acetate film was liable to

speed l(>r _l_'lmm sound tracks of 18" per second. become brittle and crack and much

This is more than twice the speed of 16mm development was being carried out by the

S.O.F. of 7.2" per second and left the problem manufacturers to improve its flexibility and

of how to marry the 16mm picture speed of 72" long term characteristics).

per secoml with the 35mm sound track speed of Harper designed a new film perforator Ref.4 to

18" per second on the one strip of 16min film. produce this new type of 16mm film stock but

this is not mentioned in the Patent

Harper's solution to this problem was to design Specification.

a special dual-purpose film printer for which he

obtained a British Patent Specification No. In order to obtain his special 16mm projection

509009 lin· which he applied on January 4th prints Harper designed a special and rather

1938. TilL~ complete specification was left on complicated dual-purpose printer. This is

May 14th 191X and accepted on July 4th 1939. described in great detail in the full Patent

Ref:J. Specification and is too lengthy and involved to

reproduce here. On

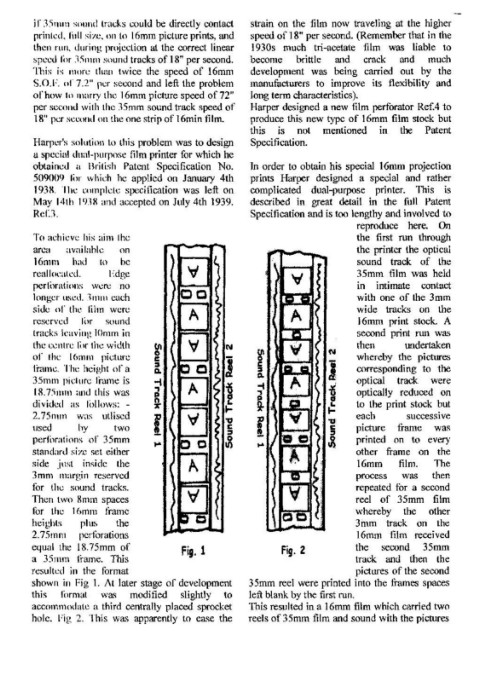

To achieve his aim the the first run through

area available on the printer the optical

16mm had to be sound track of the

reallocated. l·:dge 3 5mm film was held

perl(mttions were no in intimate contact

longer used. lrnm each with one of the 3mm

side of the lilm were wide tracks on the

reserved l(>r sound l6mm print stock. A

tracks leaving IOmm in second print run was

the centre llx the width then undertaken

U\ N

of the 16mm picture 0 whereby the pictures

frame. The height of a c ! corresponding to the

:1

0.

35mm picture frame is , optical track were

-t

18. 75mm <uH.I this wa-; '1 optically reduced on

D

divided as l(>llows: - 2- I. to the print stock but

2.75mm was utlised 1- each successive

"0

used by two l c picture frame was

!

:1

perf(mttions of 35mm ... ~ printed on to every

standard size set either other frame on the

side just inside the 16mm film. The

3mm margin reserved process was then

for the sound tracks. repeated for a second

Then two 8mm spaces reel of 35mm film

for the 16mm frame whereby the other

heights plus the 3mm track on the

2.75mm perforations 16mm film received

equal the 18.75mm of Fig. 1 Fig. 2 the second 35mm

a 35mm frame. This track and then the

resulted in the format pictures of the second

shown in fig I. At later stage of development 3 5mm reel were printed into the frames spaces

this l(>rmat wa<> modified slightly to left blank by the first run.

accommodate a third centrally placed sprocket This resulted in a 16mm film which carried two

hole. Fig 2. This was apparently to ease the reels of 35mm film and sound with the pictures