Page 18 - RD_2021-12

P. 18

KODAK FILM PROCESSING - 1960s

The cartons containing films to be processed, end four feet cut off and discarded.

arrive at the Kodak Processing Station, in Identification numbers are then punched in

Melbourne, in bulk mail bags. When the mail the fresh end of each film and also in its yellow

bags are opened, the cartons are sorted carton. Forty films are numbered and spliced

into 8mm or 16mm rolls or together using special brass rivets.

magazines, monochrome or colour. In the

case of magazines, the two retaining screws in The resulting roll of film with its

the case are removed to enable the film to be accompanying cartons are then transferred to

removed more easily in the darkroom. the processing department and fed into

the machines. As it is led off its spool, an

All cans of film are opened in 'green light' and automatic detection device follows the edges

the end two or three inches only examined. of the film and checks for any nicks, cuts,

This is to make sure that only Kodachrome tears, etc. This machine might detect a splice

film is contained therein - occasionally the but it is unlikely that it would detect a film

can contains other types. which has been broken and stuck together with

sticky tape.

The roll of film is then replaced in its

yellow carton and passes with If film stuck together in this manner is not

numerous others in the batch into picked up by this detector, the sticky tape will

the processing room. In total darkness, each soak off in the chemicals baths which

roll of film is removed from its box and the follow, and the long line of film will

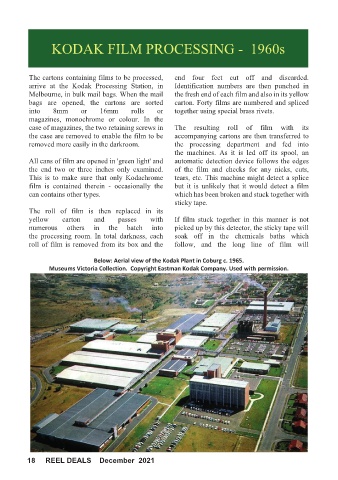

Below: Aerial view of the Kodak Plant in Coburg c. 1965.

Museums Victoria Collection. Copyright Eastman Kodak Company. Used with permission.

18 REEL DEALS December 2021